Piling Mat Material

Bulk dig and CBR test. Add a commercial fabric softener to the rinse cycle.

Piling Mat Design Rsa Geotechnics

Piling Mat Design Rsa Geotechnics

This contributes to our commitment to re-use as much on-site arisings as possible and also saves on transport of materials with its cost and environmental implications.

Piling mat material. Whether the job calls for screw piling sheet piling or bore piling a competent foundation is crucial. The term working platform is restricted to ground supported platforms constructed of granular material. Hire or Buy Piling Rig Mats.

The ingredients in fabric softener coat the fibers of the fabric so that abrasion is lessened. Some piling techniques will cause groundwater to be deposited on top of the platform and this quantity must be added to that from rainfall and any rising groundwater table. How to construct a piling mat in just over 60 seconds About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features 2021.

In this article we briefly study about the materials used in the construction of pile foundation its advantage and disadvantages. This is then covered with granular material particle size normally 75mm down to dust laid to the thickness specified in the design. Piling Rig Matting Solutions Platform issues piling up.

A very helpful spreadsheet for designing working platforms for tracked plant piling platform for piling rig sheet piling righandler or other ground treatment machinery. A traditional method of constructing a piling mat is to import and layer stone. Allows to design working platforms with geosynthetic reinforcement commonly known as geogrids.

Durable piling rig mats from Timbermat create a solid stable platform and safe access routes for piling rigs on unstable ground. The spreadsheet is very easy to use and requires minimum input. In contrast to this method Ash Remediation Management offer on site stabilisation of material to piling mat standards.

Depending on the specific requirements of the piling rig design the piling mat is typically comprised of a geotextile membrane laid on the prepared subgrade soil surface. 20 tonne loads supplied from our Tilbury Dock facility and placed using a dozer and then compacted using a Bomag 120 vibrating roller. This enables steel to be placed flush with the piling mat thus enabling the rig and attendant excavator an unobstructed site reducing the risk for pile.

The enzyme will help break down cotton pills and remove them. Piling mats are a working platform used for construction plant such as piling rigs or mobile cranes. The material was delivered in approx.

Line dry woven fabrics and dry knitted garments on a flat surface. Neil Foundations Systems would recommend that the top of the mat is generally 640mm above pile cut off level. Piling Platform Piling Mat Design Spreadsheet Description.

More than 300 piles were then driven to a depth of up to 20 metres using a 69 tonne rig for the first 2 units. We have achieved specifications of in excess of 30 CBR dependent on the ground type. Also if the piling technique employs a support fluid then this must also be taken into account.

With our piling mats designed to join together almost seamlessly you can cover over larger areas or lay a long. This can be an expensive and unsustainable method with the transport alone adding numerous unnecessary lorry movements. Waste materials from demolition can be used for piling mats crushed brick concrete and cement-based products to create 6F2 from 75mm down to dust in line with the Highways Specification 600 Series.

The height of the top of the piling mat needs to be agreed. Avoid the clothes dryer. Driven piling whether precast or cast insitu will probably require pre-boring of.

They provide a stable base on which plant can safely travel and operate. Each piling mat is made of strong durable and sustainable timber in either European or tropical hardwood species. Save time on ground preparation and avoid messy remediations with DuraBase composite mats.

Due consideration must be given to the piling process employed. With a 105mm thick core it can reduce or even eliminate the amount of imported fill required. CONSTRUCTION SITE 02 - Step by step guide to piling mat construction.

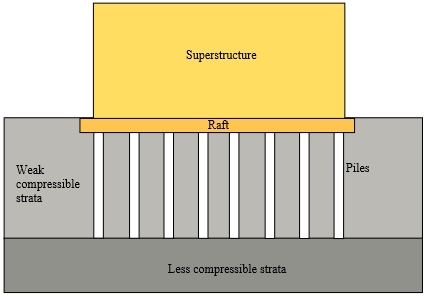

Platform designed by IDH. Different types of material used in the pile foundation are cement steel timber and plastic which are a slender structural member installed in the ground to transfer the structural loads to soils at some significant depth below the base of the structure.

Piling Mat Design Rsa Geotechnics

Piling Mat Design Rsa Geotechnics

Piling Mat Designing Buildings Wiki

Piling Mat Designing Buildings Wiki

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Working Platforms Geosynthetics

Piling Mat Designing Buildings Wiki

Piling Mat Designing Buildings Wiki

How To Read Construction Drawings 04 Low Level Piling Mat And Cbr Test Youtube

How To Read Construction Drawings 04 Low Level Piling Mat And Cbr Test Youtube

Piling Mats Concrete Batching Plant Uk

Piling Mats Concrete Batching Plant Uk

Piling Mat Stabilisation Ash Remediation

Construction Site 02 Step By Step Guide To Piling Mat Construction Bulk Dig And Cbr Test Youtube

Construction Site 02 Step By Step Guide To Piling Mat Construction Bulk Dig And Cbr Test Youtube

.ashx?h=525&w=700&la=en-GB)

A Level Playing Field New Civil Engineer

A Level Playing Field New Civil Engineer

Https Www Istructe Org Sitefiles Handlers Downloadfile Ashx Productid 772

Posting Komentar untuk "Piling Mat Material"