Piling Mat Design

If expert assistance is required the services of a competent professional should be sought. Reduce ground to required level for piling Proof roll the substrate Dig out soft spots and fill them with 6F5 Proof.

Piling Mat Design Rsa Geotechnics

Piling Mat Design Rsa Geotechnics

We are utilising crawler cranes that are inducing ground bearing pressures in the region of 50Tm2.

Piling mat design. Can anybody point me in the right direction for the design of simple pile mats. The spreadsheet is very easy to use and requires minimum input. The piling mat design are available at mouthwatering mega discounts.

Safety is critical when using mobile cranes piling rigs and other heavy plant on construction sites particularly over weak and variable ground. Achetez empilage design mat à des prix abordables tout en ajoutant une décoration supplémentaire à une maison. This inspection must be recorded and photographic.

If you need to print this. BlockWalls produced working drawing for the site to determine the number of blocks required. All piling mat working platforms shall be subject to the requirements of BS 59752008 Code of practice for temporary works procedures and permissible stress design of falsework.

We are operating on a crushed concrete piling mat 600mm deep on top of London clay. 25 31 Lifting Plan Check List 32 Inspection form Permit to Load 30 Check Lists and Inspections. The solution was to build a solid piling mat that would take the loads.

A wall was designed 18m wide x 3m high. This guidance has been produced by the Federation of Piling Specialists It is not intended to be used as a design method. A suitable design brief will have been provided to the Temporary Works Designer.

Piling Platform Piling Mat Design Spreadsheet Description. The type and size of crane being provided 31 Lifting Plan Check List A check list should be used to ensure that the lifting plan. More often than not a reduced thickness of working platform can be achieved resulting in cost saving and time saving on ever decreasing contract programmes.

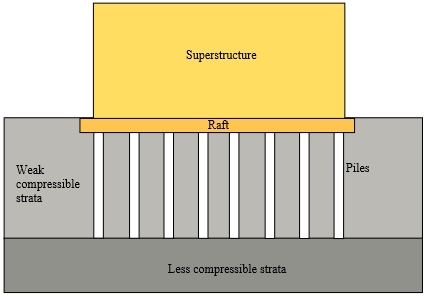

Piling mats are working platforms designed specifically to carry the heavy static and dynamic loads from piling rigs their support cranes and associated equipment. The general process of pile mat construction carried out by a team of highly competent personnel is as follows with the design engineer approving each stage before work continues. Piling mats are a working platform used for construction plant such as piling rigs or mobile cranes.

Design and installation of piling mat Do not under-estimate the importance of the piling mat. Whats needed is a safe working platform. The wall was to be built using interlocking concrete blocks a solution BlockWalls could provide.

Although every effort has been made to check the accuracy and validity of the. Ground Bearing PressuresPiling Mats. Ground Bearing PressuresPiling Mats3.

Additional Piling Mat Requirements All piling mats must be visually inspected by a competent individual once they have been constructed to formation level. Allows to design working platforms with geosynthetic reinforcement commonly known as geogrids. A very helpful spreadsheet for designing working platforms for tracked plant piling platform for piling rig sheet piling righandler or other ground treatment machinery.

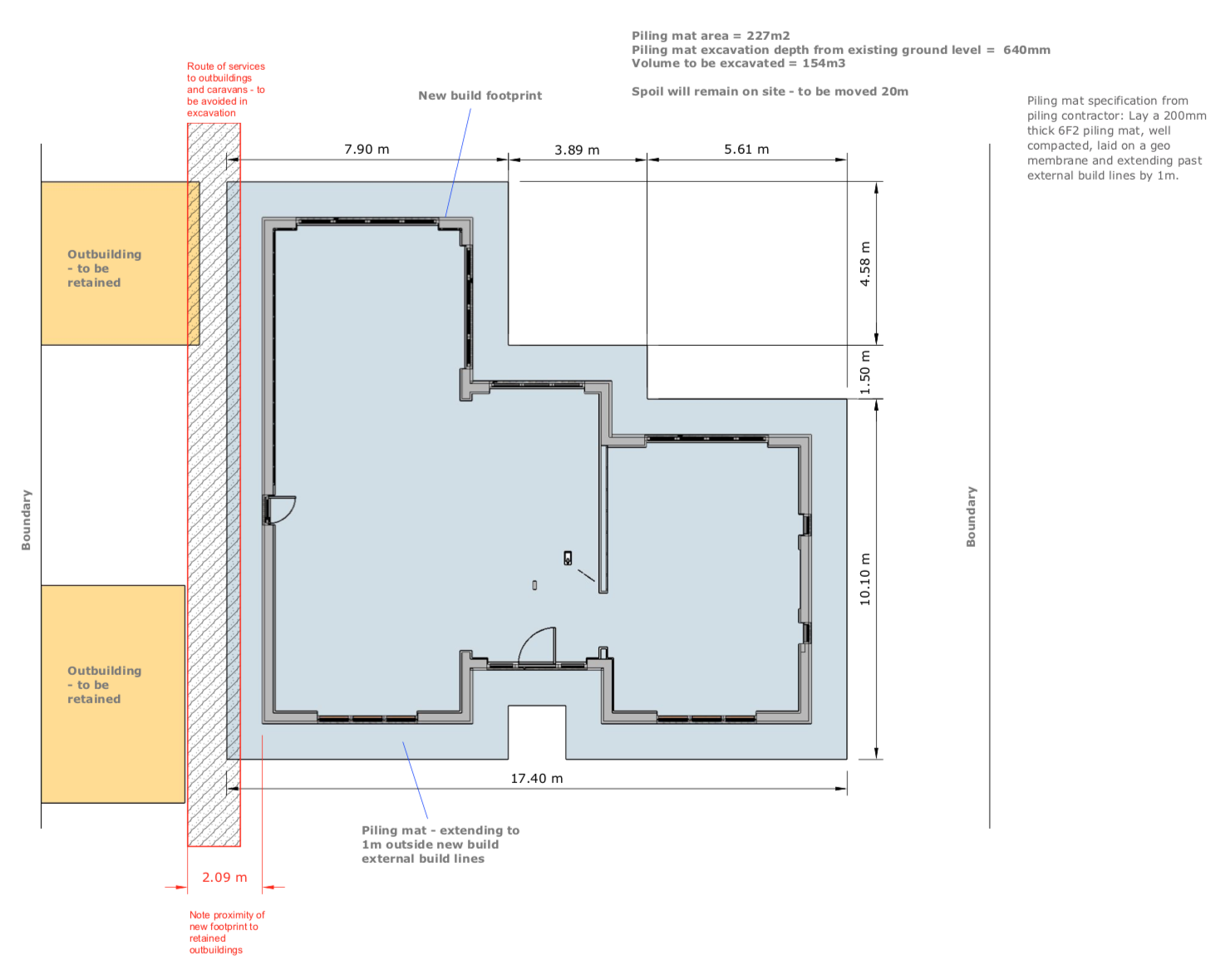

Platforms should be designed according to the actual rig loadings supplied by the piling contractor. The following must be considered in order to design the piling mat to suit the ground conditions and the piling equipment being used so that plant will not bog down in muddy conditions. Tensars T-value method enables a more accurate assessment of the positive effect of stabilising geogrids on the bearing capacity of granular working platfor.

By taking early Plate Bearing Tests on proposed piling areas we offer a piling mat design service backed by our temporary works engineers. The term working platform is restricted to ground supported platforms constructed of granular material. 26 The position of any lifts drawn to scale on plan including dimensions.

Tensar TriAx Geogrids mechanically interlock with a well graded granular fill resulting in particle confinement which amongst other benefits increases the bearing capacity of. They provide a stable base on which plant can safely travel and operate. How Tensar geogrids help.

Design of granular working platforms for construction plant A guide to good practice Published April 2019 Published by Temporary Works Forum co Institution of Civil Engineers One Great George Street London SW1P 3AA England First Published.

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Piling Mat Designing Buildings Wiki

Piling Mat Designing Buildings Wiki

Piling Mat Design Rsa Geotechnics

Piling Mat Design Rsa Geotechnics

Piling Mat How To Reduce Cost Foundations Buildhub Org Uk

Piling Mat How To Reduce Cost Foundations Buildhub Org Uk

Working Platforms For Tracked Plants Idh Design

Working Platforms For Tracked Plants Idh Design

Piling Mats Concrete Batching Plant Uk

Piling Mats Concrete Batching Plant Uk

Https Www Istructe Org Sitefiles Handlers Downloadfile Ashx Productid 772

Reinforced Piling Platform Northshore Stage 1 Hamilton

Reinforced Piling Platform Northshore Stage 1 Hamilton

Working Platform Design Spreadsheet To Bre 470

Working Platform Design Spreadsheet To Bre 470

Https Www Rbkc Gov Uk Idoxwam Doc Other 1045985 Pdf Extension Pdf Id 1045985 Location Volume2 Contenttype Application Pdf Pagecount 1

Reinforced Concrete Pile Caps Details Reinforced Concrete Building Foundation Pile Foundation

Reinforced Concrete Pile Caps Details Reinforced Concrete Building Foundation Pile Foundation

Piling Mat Designing Buildings Wiki

Piling Mat Designing Buildings Wiki

The Service Ga S Details Traditional Autocad Drafting Service Our Traditional Drafting Service Is Adaptable To Suit Specific Standards Of Each Client Our Team Is Flexible And Will Follow Specific Cad Manual Of Each Client To Preserve Their Layouts

Working Platform Design Spreadsheet To Bre 470

Working Platform Design Spreadsheet To Bre 470

Https Www Istructe Org Sitefiles Handlers Downloadfile Ashx Productid 772

Posting Komentar untuk "Piling Mat Design"